R&D

Mitlan is an innovative company that operates in the construction and civil engineering sector, providing products and services that aim to improve the quality and safety of urban and transport infrastructure. Since its establishment, Mitlan has made a strong commitment to the research and development of new solutions as a result of the realization of several R&D projects.

The following are some of the R&D projects led by Mitlan, as well as future lines:

EMPLEA-TU-2015 (“EMP-TU-2015-4173”) – Ministry of Economy and Competitiveness

The following main activities were carried out:

- Study of the connections between the MC® and their complements: geogrids and anchors.

- Technical feasibility study of alternative applications of MC® in civil works.

This project lasted 3 years.

Horizonte Pyme 2015 (“SME-2015-0643”) – Ministry of Economy and Competitiveness

The following main activities were carried out:

- Prototyping activities and quality certifications

- Laboratory checks and FEM simulations

- Commercial feasibility study of the main applications of the MC® in civil works.

This project lasted 6 months.

SME Instrument Phase I (“Grant Agreement 745148”) – European Commission

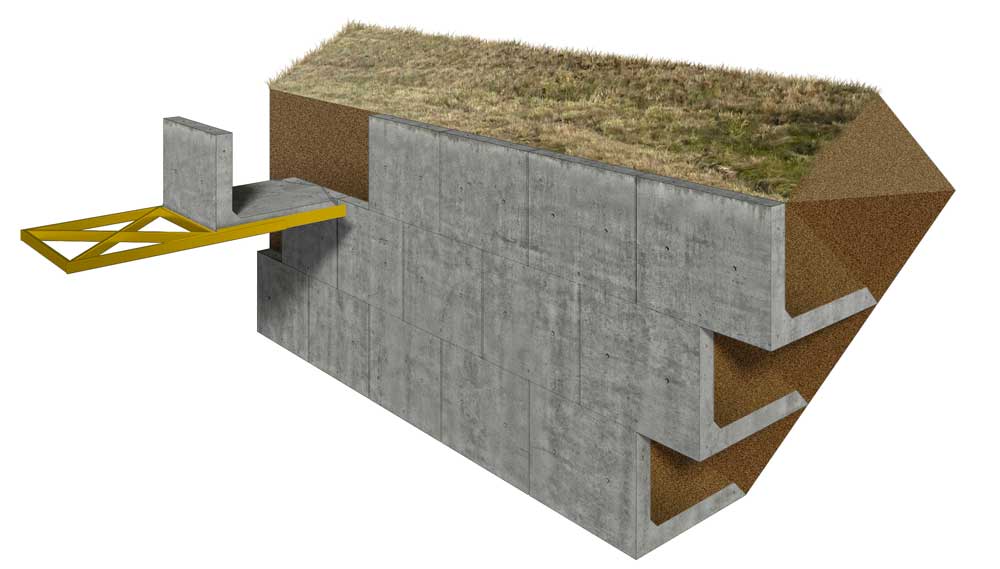

- Technical and commercial feasibility study of the 4S BLOCK® solution

This project lasted 6 months.

Programa Neotec 2016 (“SNEO-20161414”) – Centre for the Development of Industrial Technology (CDTI)

Mitlan’s business plan has been developed, assuming a qualitative leap for both the MC® and 4S BLOCK® building system. Through this program the company has begun its expansion plan within new regions in Spain and new European markets, extending the scope of its industrial property titles.

This project lasted 2 years.

Internal R&D project – “MC® Hinca” application development

The objective has been to develop a MC with a special design, made of high-strength concrete and with the particularity that its long section will be reinforced by a steel finish.

The excavation process is carried out in a staggered manner as follows: the land that is in front of the place where we want the piece to be placed and deemed appropriate to be able to place it loosely, but without exceeding safety reasons, is removed. Then, it is placed using some existing technique in the market in this regard; by hydraulic jacks, by striking with mass of inertia, etc. It is convenient that the action in question, whether its push or hit, be applied directly on the lower part of the MC® and never on the vertical section. The addition of water at the free end of the MC® will greatly facilitate the operation.

This project lasted 10 months.

Fast Track to Innovation – European Commission

The company is currently preparing the proposal.

It will be presented in the call of October 22, 2019, with an estimated budget of € 3M and 5 collaborating partners.

This project will last 2 years.

Other lines of work

- Study of formwork molds for the manufacture of MC® on site.

- Effect of confinement achieved by the MC® on the properties of a given soil and its parameterization.

- Friction optimization in the interfaces of terrain-containment structure interaction.

- Influence of MC® support dilation.

- MC® behavior in dynamic efforts.

- Study of the application of the 4S BLOCK® paver.

- Type 6S BLOCK® development.