Concrete cobblestones

There are several types of cobblestones in the market depending on their geographical location, customs, etc. Traditionally, they have been made of stone, often granite, but ceramic and concrete can also be manufactured.

WHAT IS A CONCRETE COBBLESTONE?

Normally the concrete paver that is used is a piece made of vibro-pressed concrete. It has numerous advantages over stone pavers: they can be given much more varied floor shapes, adopt different colors and have a reduced price.

In general, the execution is performed in two ways: using sealing sand to ensure joint work (“euro-cobblestones”) or using cement mortar for bonding (as in the case of ceramic or stone pavers).

As a fundamental geometric characteristic of all these cobblestones we can say – except for very few exceptions – that although its plan form can be very varied in the contour of the piece we only have vertical planes, that is to say that a piece and the adjacent one do not they touch and the union between them is only obtained through the mortar or sand.

DESCRIPTION OF 4SBLOCK®

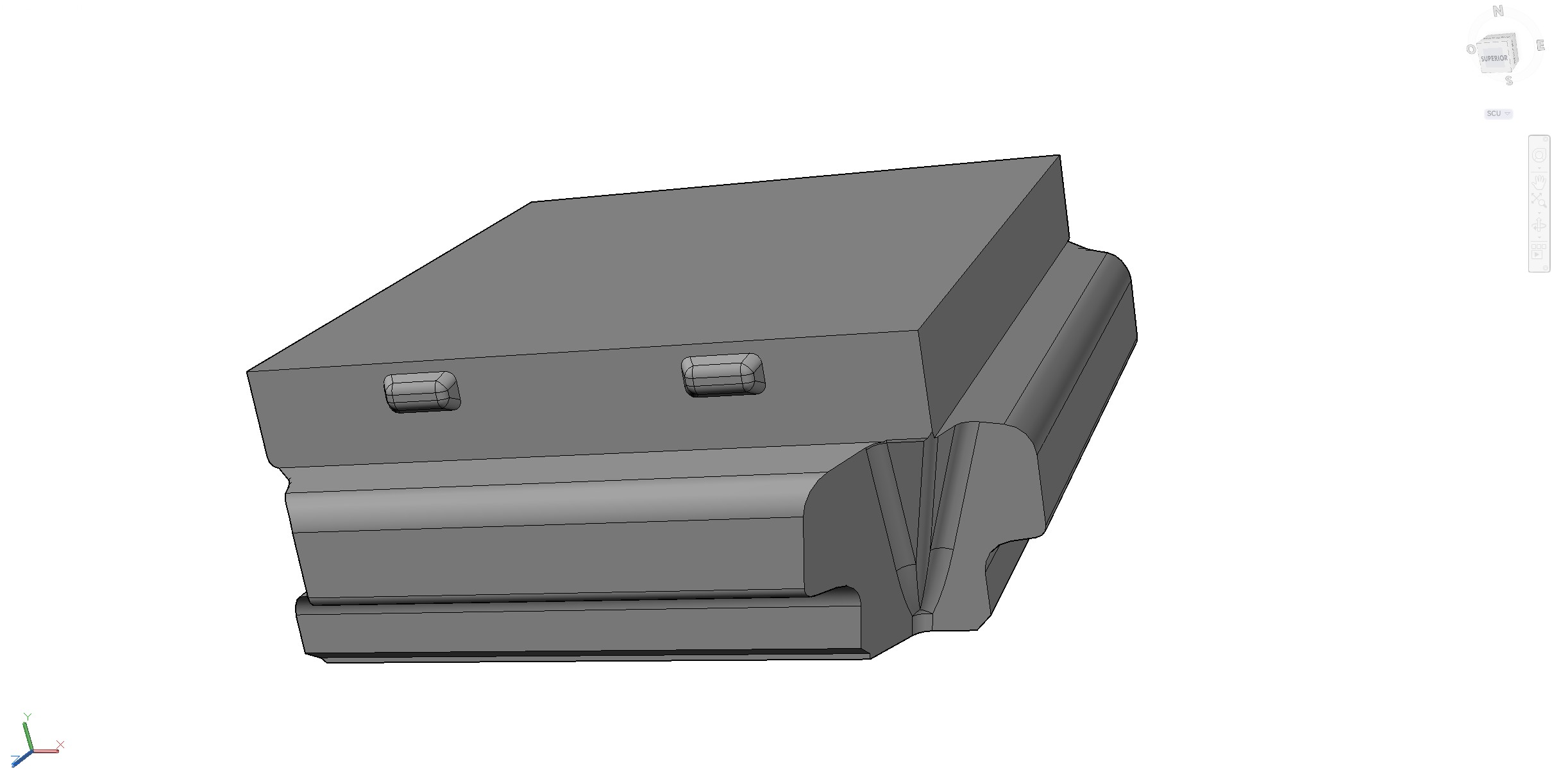

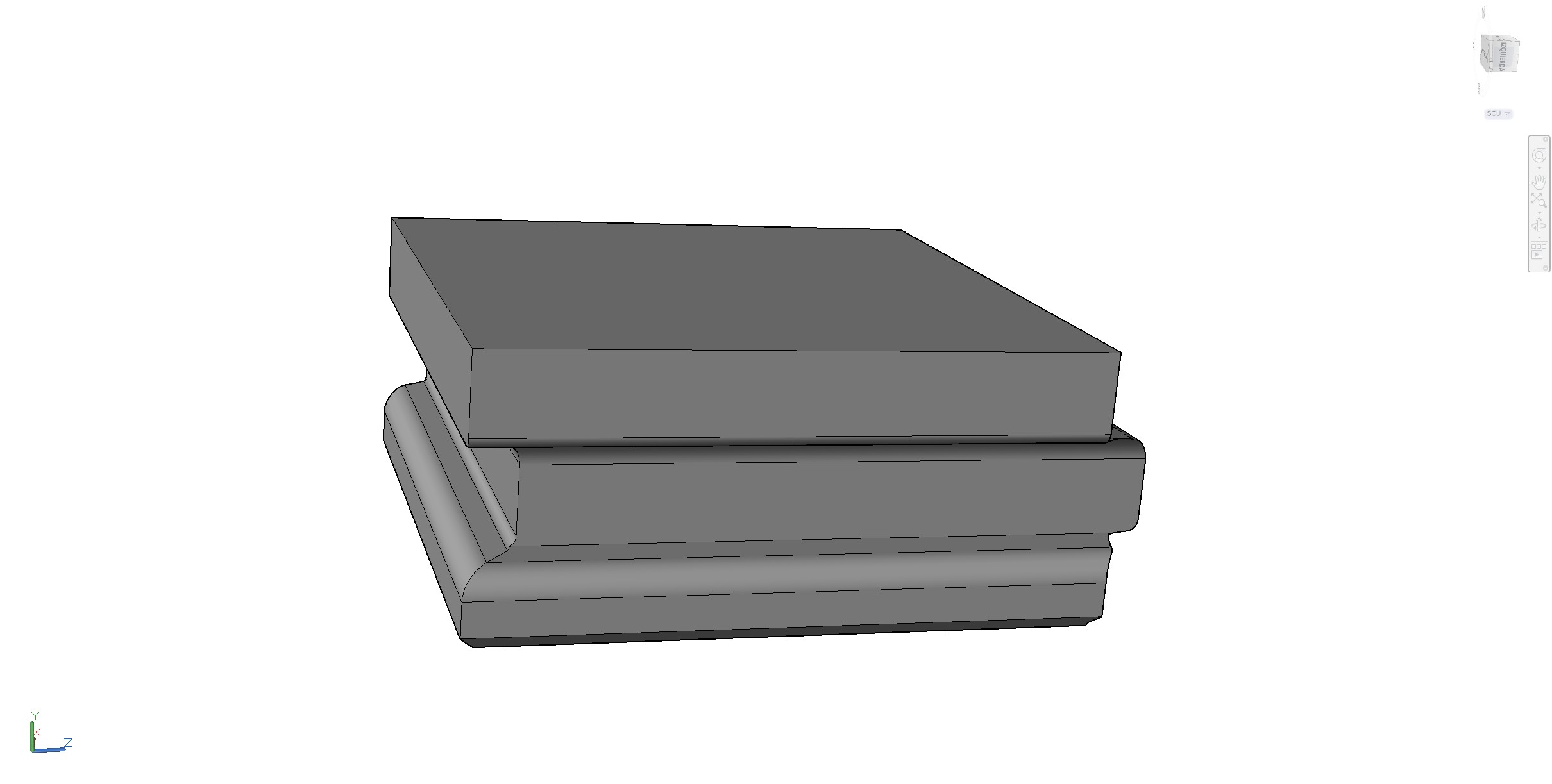

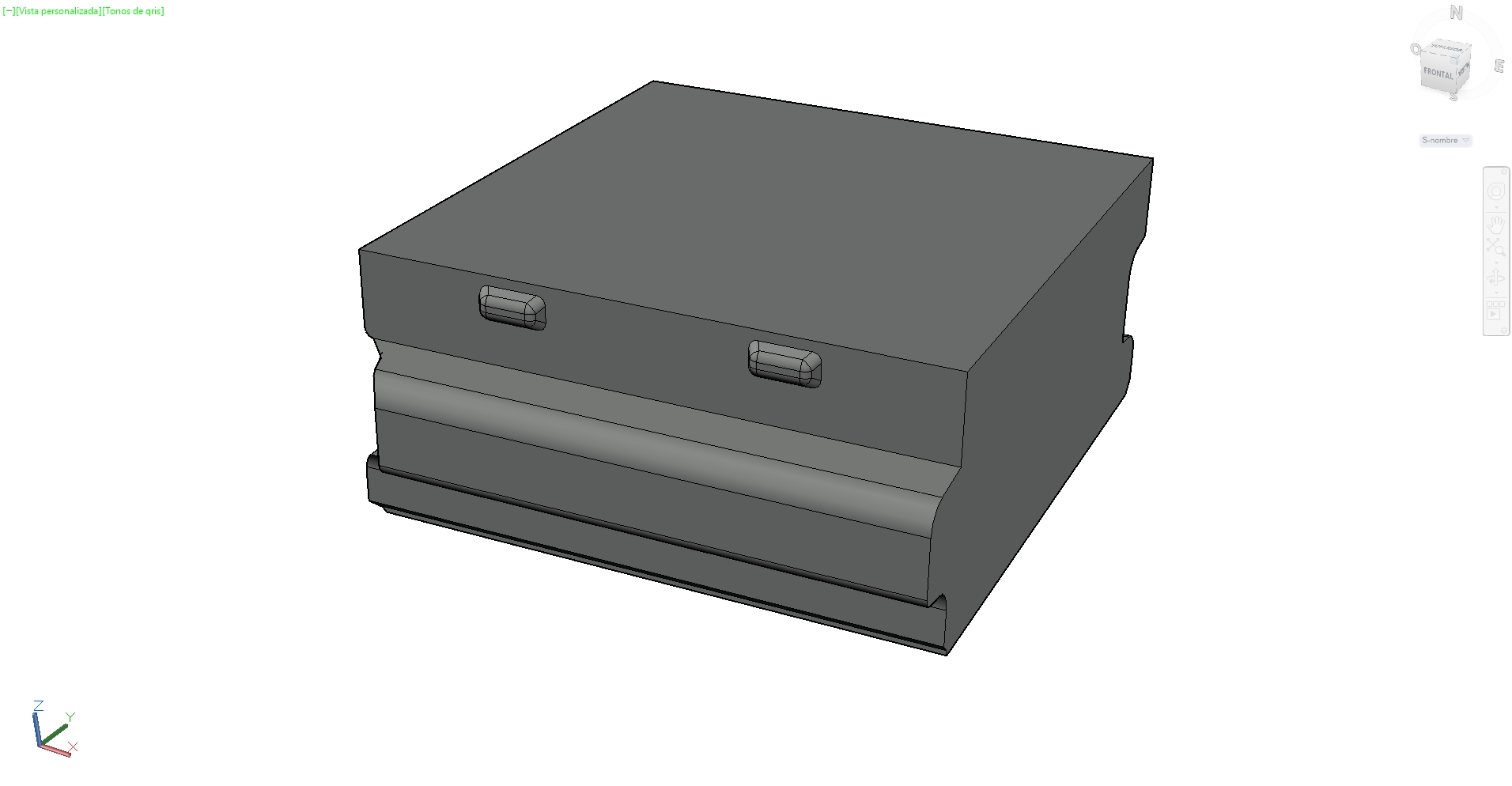

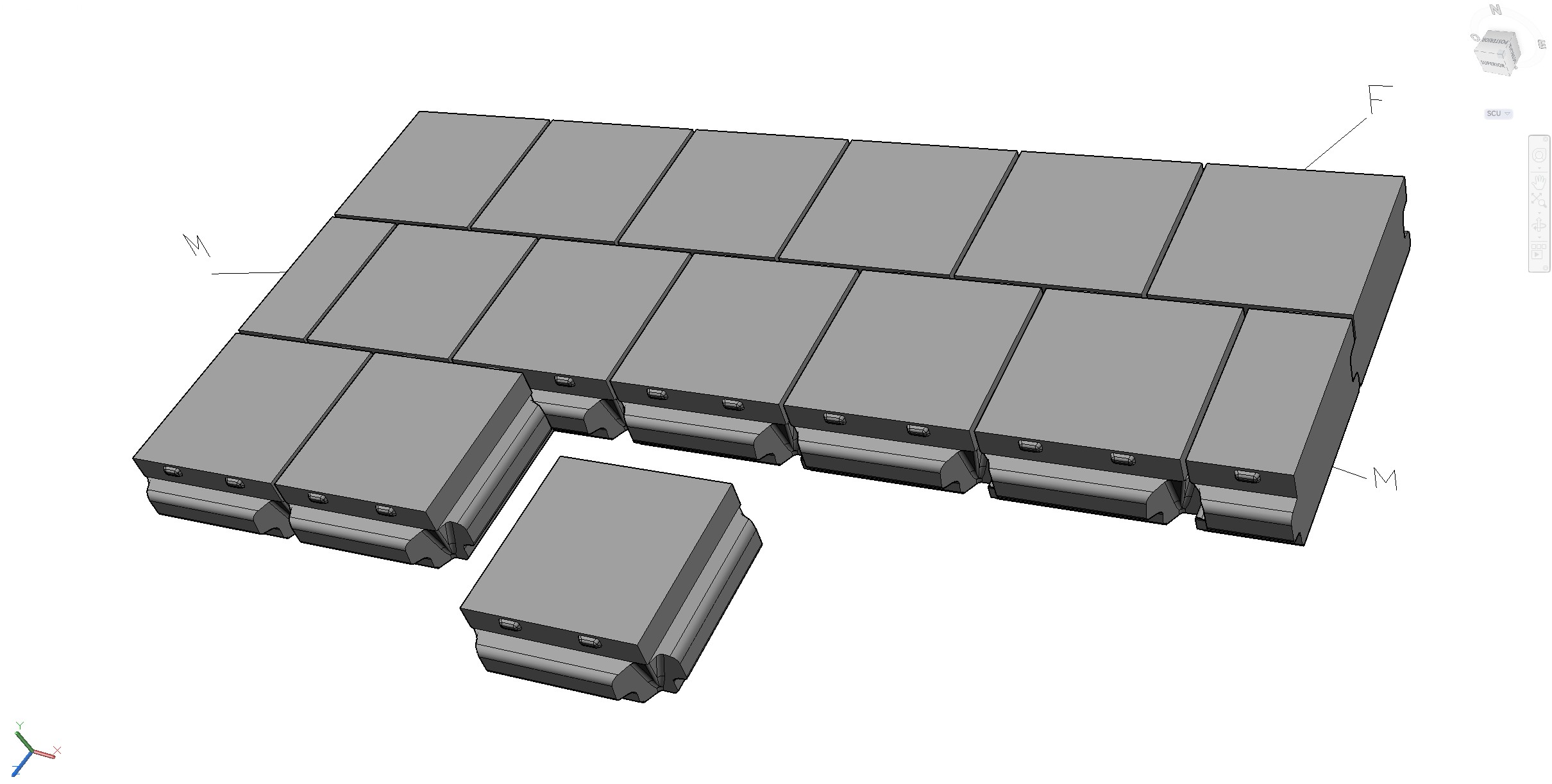

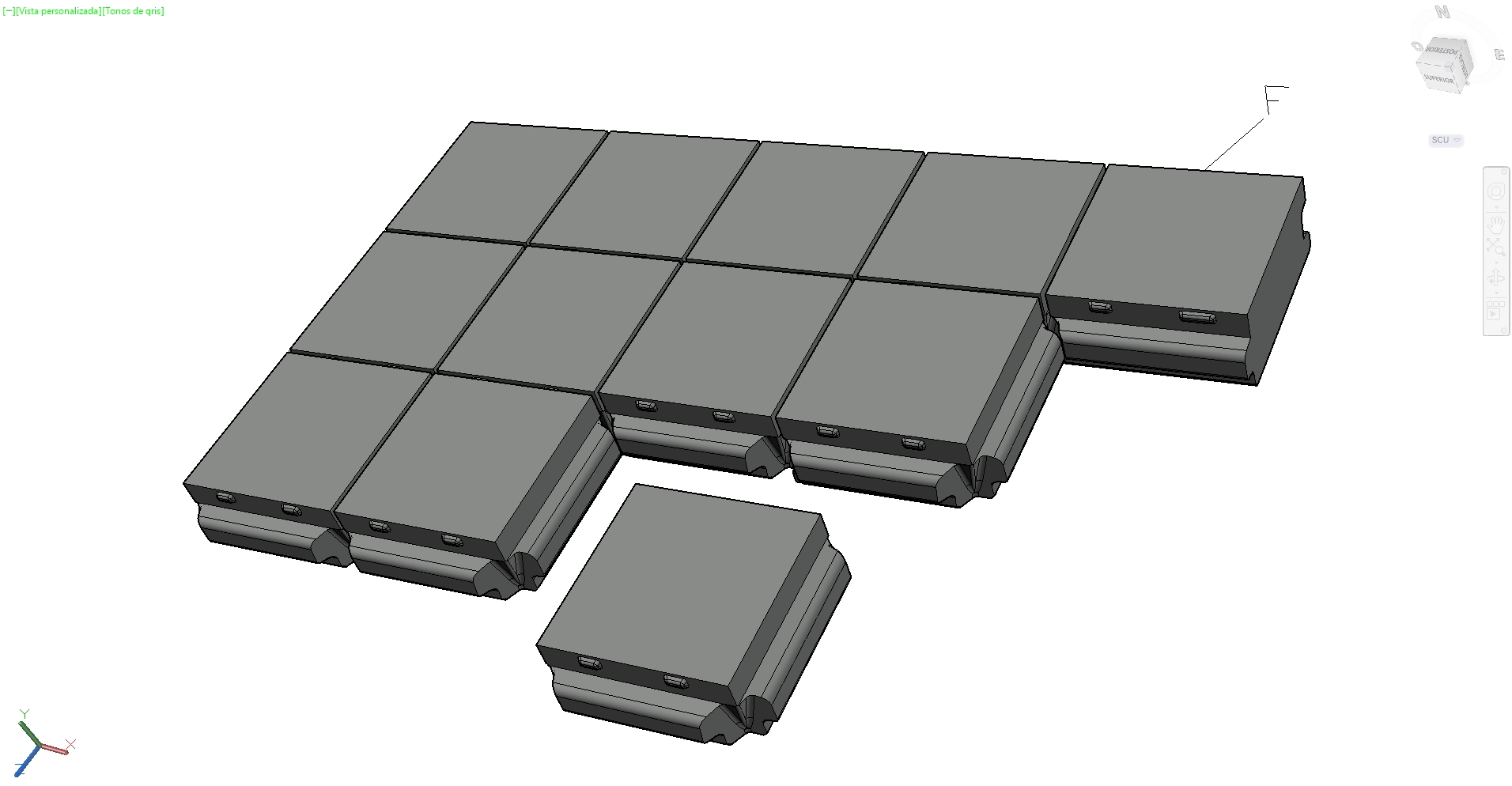

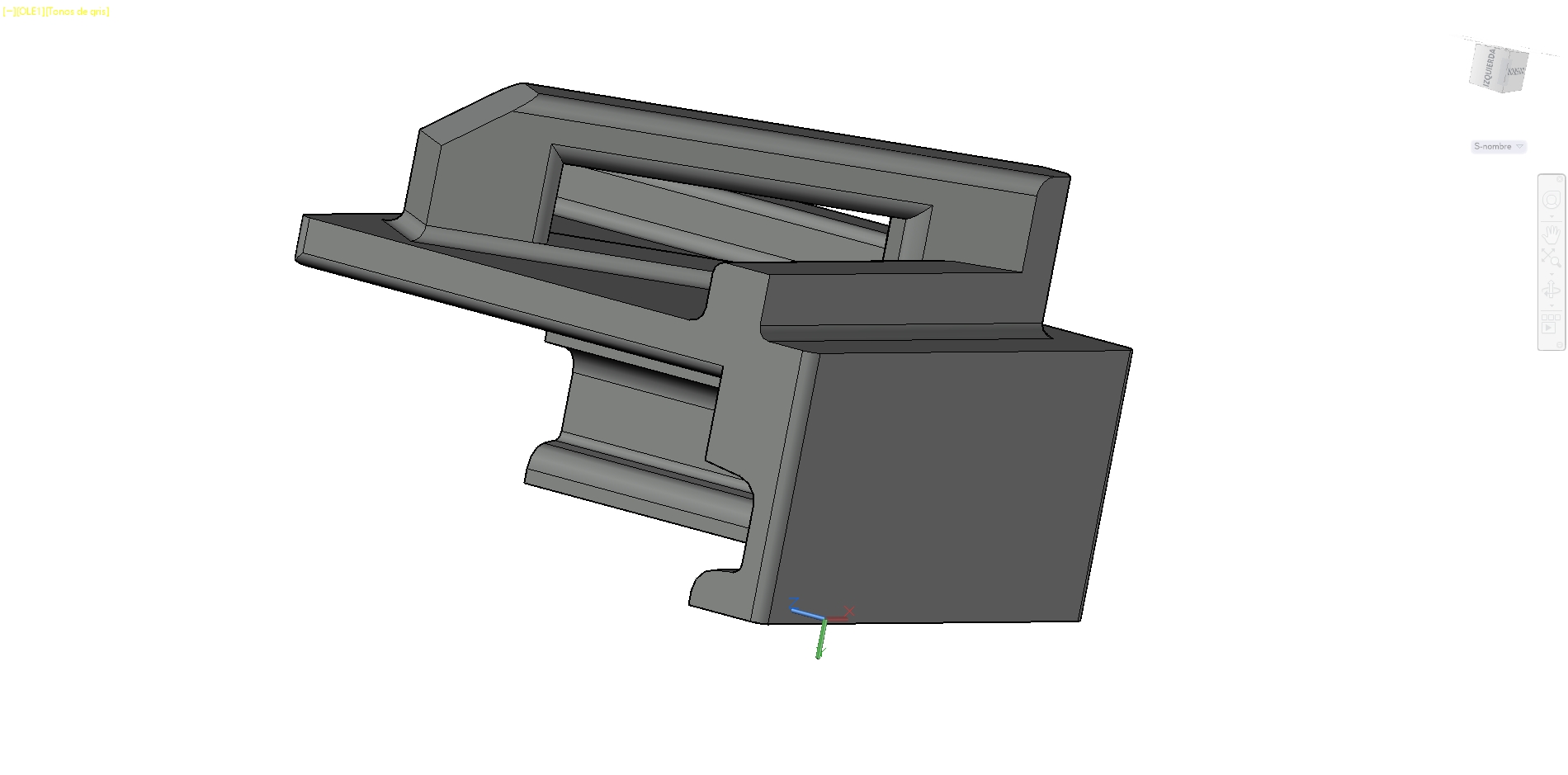

Our 4S BLOCK® ADR paver is in the shape of a quadrangular prism with a contour that is not vertical but formed by two adjacent contiguous faces and the other two adjacent contiguous faces, as we can appreciate in the following figures. The dimensions are 175 x 175 x 80 mm.

The upper and lower faces are both squares, but the upper ones have a side 4 mm less than the lower ones and thus a joint is left on the upper face while the lower faces are touching. This fact is necessary to enable the entry of sand or mortar where appropriate.

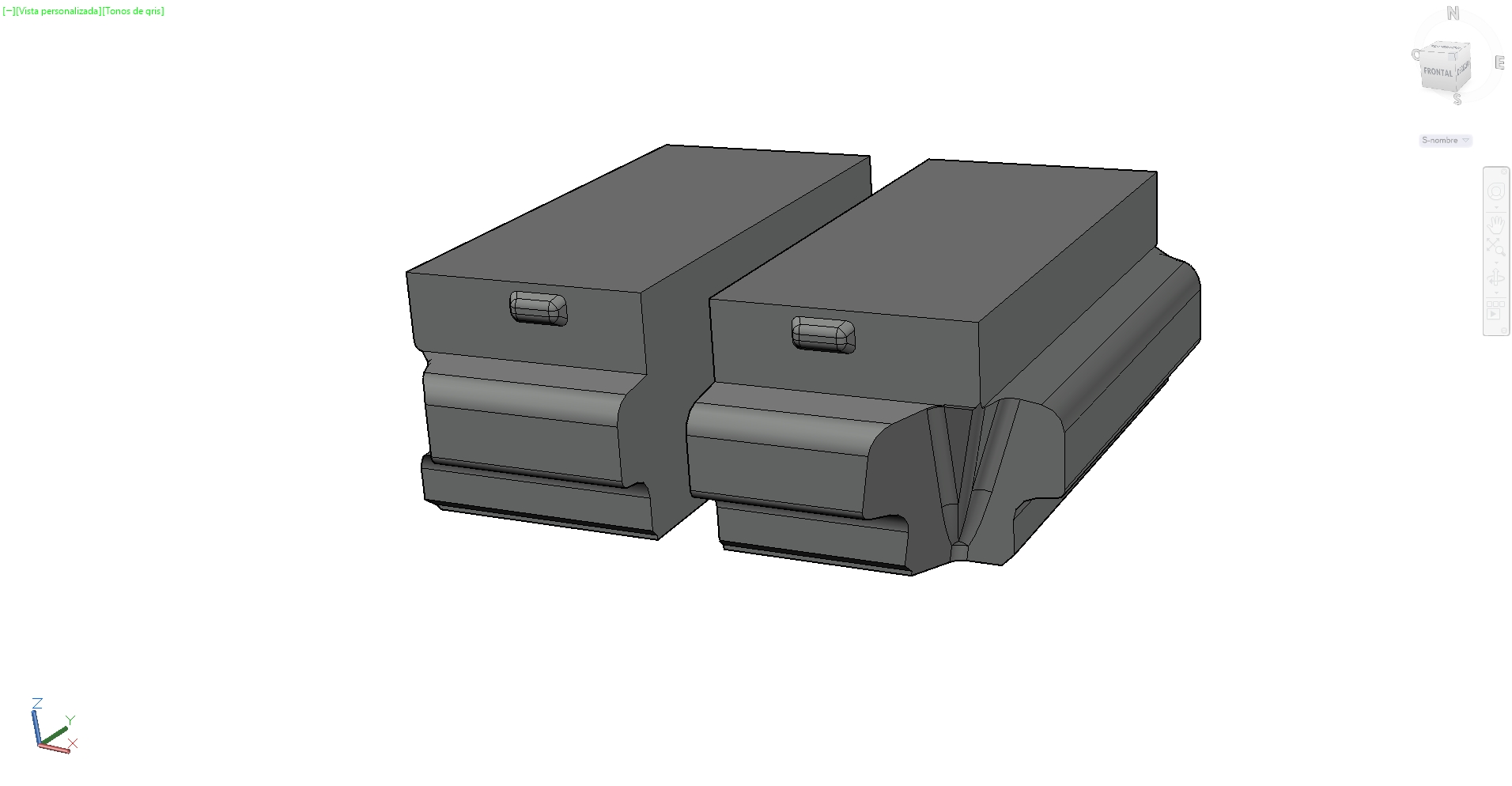

All the pieces are the same except for the two “male or female half pieces” that come from dividing a normal piece into two or the “final piece” that makes a male face of a normal piece flat. Through precise cuts in a “final piece” we can reach what we call “masterpiece” that has two flat contiguous faces and the other two females without the lower lip. These masterpieces are used to conclude an assembly or initiate a disassembly where appropriate and are placed in their own places to be subjected to less loads, since the connections with the adjacent ones are reduced. The “male-female half pieces” and the “final piece” are shown in the following pictures.

Our 4S BLOCK® ADR paver can use three possible types of connection: draining (without binder), with mortar and sand. As for the relative arrangement between pieces, they can be placed counterbalanced or mat-assembled or simply aligned or arranged in both directions, as shown in the following figures.

When the draining option is used to place the pieces, obviously no binder is used, so that the path is free for the water that we will evacuate through the support layer that will have a draining character. This option has a reduced bearing capacity but higher flexibility to adapt to the movements without being overstressed.

When the mortar option is used to place the pieces, the binder will be a very fine sealing mortar to penetrate between the tongue and groove. In this case the resulting pavement will be tight, and its bearing capacity will be maximum. Unlike in the previous case, deformations in the support cause overstress in the pieces.

When the sealing sand option is used in the same way it is used with “Euro-cobblestones”, the resulting pavement will be tight, and its bearing capacity will be large. As for the deformations we are facing an intermediate case between the previous two.

Within the field of R&D there are many possibilities that will have to be tested, such as using as a joint between pieces a bituminous binder that can provide a suitable elasticity and sealing, use the 4S BLOCK® ADR as a base where you can adhere fine resin slabs of marble, stone, slate, etc…

Currently, the 4S BLOCK® BDR is already designed, which, like the 4S BLOCK® ADR, interlocks between adjacent pieces in the vertical direction and also a block for movements that occur in the horizontal plane, which is relevant as a response for braking phenomena that have a great impact on pavement failures.

ADVANTAGES OF OUR 4S BLOCK® PAVER AGAINST OTHER TYPES OF PREFABRICATED COBBLESTONES

A priori we can say that our pavers have properties similar to the “Euro-cobblestone” in terms of available colors, non-slip, etc. since both are manufactured by the same system and the same concrete. In the case of 4S BLOCK®, when the structural behavior requires it, the concrete will have the addition of polymeric fibers, which implies a direct improvement in the intrinsic properties of the concrete: better traction behavior, greater fire resistance, better retraction behavior, better response to impacts, etc.

Our 4S BLOCK® paver allows to form a structure assembled in the 4 directions. The immediate consequences are as follows:

- The load acting on our pavement is distributed in the 4 directions and therefore the pressure that we make on the support is lower and a lower bearing capacity is needed. We specify: Our 4S BLOCK® ADR paver needs a lower bearing capacity than the standard system.

- The narrow tongue and groove that remains between adjacent pieces apart from dealing with transmitting actions in all 4 directions prevents relative movement between them. We specify: Our 4S BLOCK® ADR paver prevents relative vertical movement between adjoining parts, so that no steps can appear as in the standard system.

- The impossibility of relative movement between parts ensures a smooth and continuous surface that reduces traffic noise and increases road safety, especially for pedestrians. We specify: Our 4S BLOCK® ADR paver reduces traffic noise and increases road safety, especially for pedestrians.

- If we do not use any binder in the assembly of the pieces, we get a draining pavement. We specify: Our 4SBLOCK® ADR paver allows to have a draining floor as an advantage over the standard system.

- The response of our pavement to the phenomena of braking and dynamics in general is substantially better since the tongue and groove allows the transmission of the forces and moments produced that end up blurred. We specify: Our 4S BLOCK® ADR paver has a magnificent response to dynamic and braking phenomena.

- Our pavement will be easily removable when it has been placed without binder or draining. It can also be disassembled when it has been placed with sand but in this case we would need a previous vibration to help disintegrate the pieces. We specify: Our 4S BLOCK® ADR paver is easily removable when it is draining and can also be disassembled when it has been placed with sand with a previous vibration.

- With the draining and removable use of our pavement we can arrange it directly on appropriate esplanades and get conditioned spaces for holding temporary events. Once concluded the acts would be dismantled for future use. We specify: Our 4S BLOCK® ADR paver can be used to condition esplanades and allow temporary events.

APPLICATIONS OF THIS COBBLESTONE MODEL

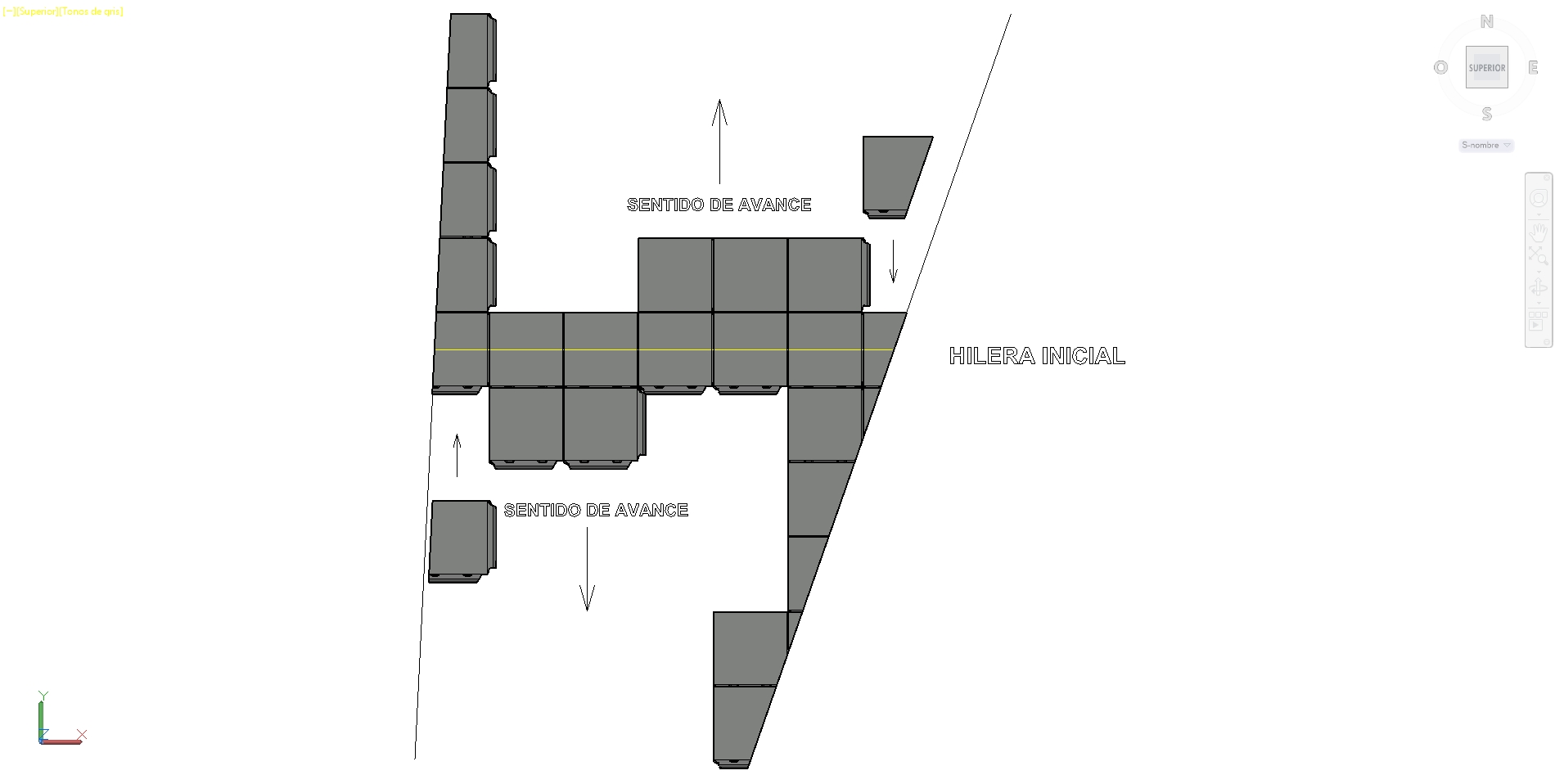

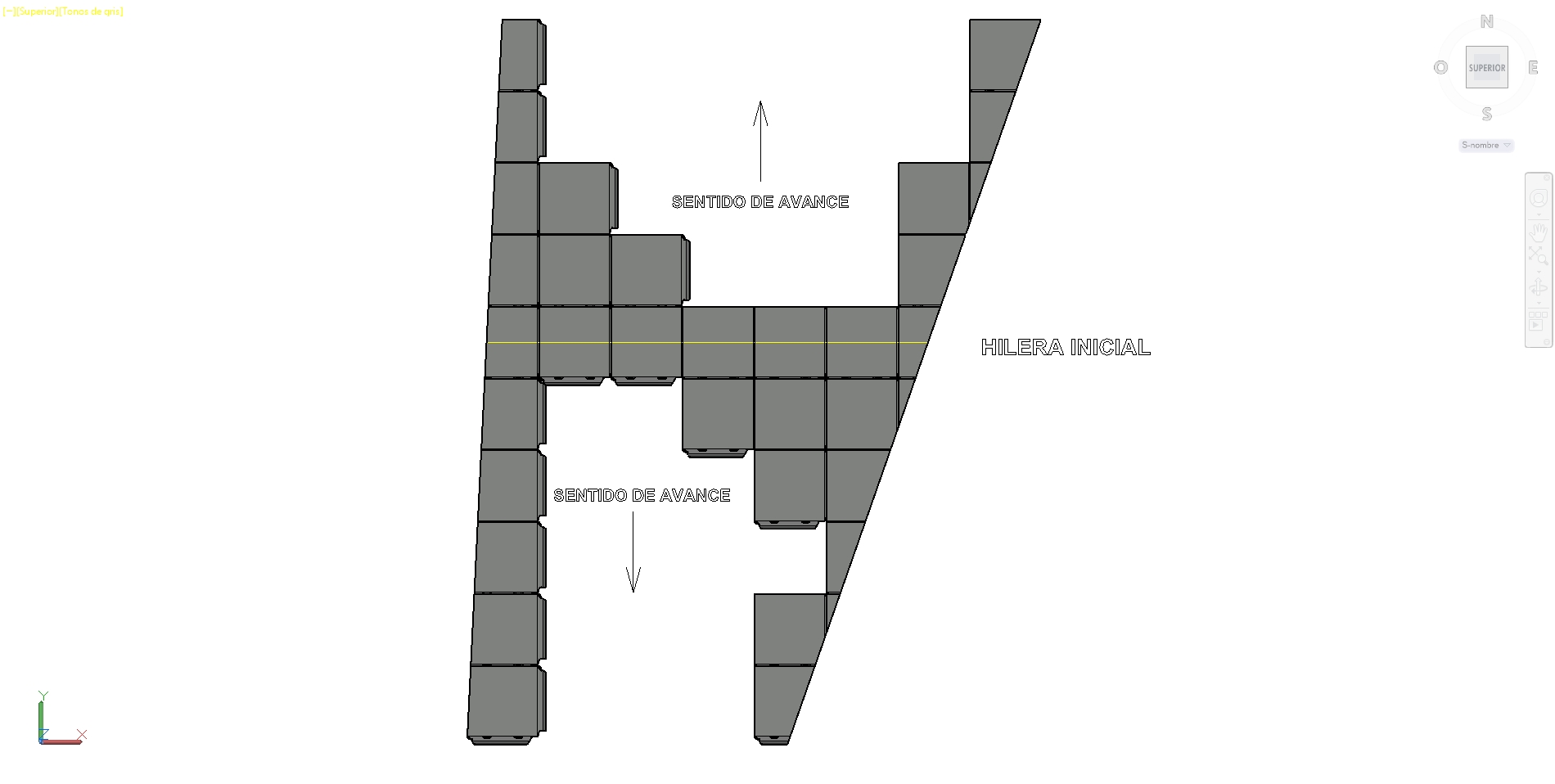

In the first place and keeping in mind that these pieces are connected to each other, certain set-up guidelines must be followed. We include as an example two figures with the ways to proceed in the assembly.

In this case, we have the initial row and then place from it the pieces on the edges that are decreasing: left edge up and right edge down. Then we continue placing pieces with the indicated directions of advancement.

In this other way, we place all the edge pieces from the beginning from the initial row. Then we continue placing pieces with the indicated directions of advancement.

In general, for each case it will be necessary to look at the ideal form of assembly.

Our 4S BLOCK® ADR paver, due to the fact that it has three different types of execution methods: without binder, with mortar and with sand, and an extensive variety of colors available, has a wide range of applications: streets, parking lots, plazas, gas stations, gardens , highway and highway shoulders, etc. We will describe some applications in more detail:

Road traffic vials: Our 4S BLOCK® ADR paver in this case will use sand or mortar binder normally as we use a flexible or rigid base. While we have the 4S BLOCK® Technical Manual that will begin to be prepared shortly by a, we will use the classic for normal pavers. In our case the fatigue of the firm will be less because the loads are transmitted distributed to the support.

The placement of the parts in this case must be counterbalanced in the normal sense to the traffic, so that the braking forces are better distributed.

Sidewalks: Our paver 4S BLOCK® ADR in this case will use sand or mortar binder normally. In the assembly, oblique edge alignments must be kept in mind and must be carried out with the direction of advance of more to less width so that the closing piece enters. The incidents in the pavement will be mounted on frames with dimensions “multiples” of the size of the 4S BLOCK® ADR so as to try to cut fewer pieces.

In relation to the “masterpieces” they are placed in their own places to be subjected to less loads: facade bends, under a bench, etc.

Squares: Our paver 4S BLOCK® ADR in this case will use sand or mortar binder normally. The assembly instructions mentioned must also be taken into account. “Modulated” tree blocks and logs will be placed as in the case of sidewalks. In the same way and in relation to the masterpieces, the appropriate sites for their location will be searched.

Cycle paths: In this case, our 4S BLOCK® ADR paver can be mounted with many finishes: draining, with mortar, with sand and with a bituminous binder, depending on the area where it is located and the effect that you want to achieve as the loads are moderate.

As for the relative mounting system between pavers and in general we can say that it will be more proper to put them against in sidewalks, road traffic vials and cycle paths due to the appearance of curves and aligned or arranged in squares and large spaces.

Terraces and gardens: As in the previous case, our 4S BLOCK® ADR paver can be mounted with many terminations: draining, mortar, sand and bituminous binder, depending on the area where it is located and the effect that you want to achieve. In this type of infrastructure, we can replace the trails that are usually available for jogging for the draining provision for reasons of saving maintenance costs.

With our 4S BLOCK® ADR paver we can do special actions such as: for example: in the immediate vicinity of a tree we leave a small tree to fit the loose trunk and between this tree and the pavement we establish a large square of 2×2 m where we use the pavement without binder and in this way we gain all the space of the big tree beds and we have a more deformable pavement in anticipation of moving by thrust of the roots.

Other types of pavements: With our 4S BLOCK® paver, in general we can carry out very varied performances.

- Boardwalks: draining use.

- Esplanades for eventual use: draining and removable use.

- We can use our 4S BLOCK® paver as a structural base where we can adhere a thin slab of finishing material: marble, polished granite, etc. (This application belongs to our R&D).

- We can think of other 4S BLOCK® large size manufactured via semi-wet process and made of reinforced concrete with the addition of fibers for use in industrial areas with large loads, airports, etc. (This application belongs to our R&D).

HOW ARE MITLAN CONCRETE COBBLESTONES PLACED?

In general, the arrangement and type of the layers to be disposed will be the one used with the normal concrete “Euro-cobblestone”. The firm will now suffer less fatigue because the distribution capacity of this system makes it transmit a lower load to the support.

Although the placement on site of the 4S BLOCK® ADR is studied by means of suction cups that manipulate groups of them from their location on the pallet, for now we have designed a tool that facilitates its handling and placement and that can be seen in the attached figure.

As already mentioned, they can be placed counterbalanced or aligned or arranged.

PRICE OF OUR CONCRETE 4S BLOCK®

The price of our 4S BLOCK® paver is very similar to that of the standard “Euro-cobblestone”, because although the concrete used is somewhat more expensive for having more resistance and also for the addition of fibers where appropriate, the production is higher due to the manufacturing method.

As in all cases the color will also influence among other factors.